Sports Field Blog

Subscribe To Email Updates

Subscribe to our weekly newsletter and we’ll send updates straight to your inbox

How Much Does a Synthetic Turf Sports Field Cost?

Google “How much does a turf field cost?” and you’ll find calculations and averages per square foot that vary wildly across websites and providers.

The truth is, how much you’ll spend on your turf is affected by complex, interdependent factors. The cost only tells you one part of the story, and there’s more to it than just the quote you get.

In this article, we’ll explore these factors and help you get an idea of what your artificial turf field might cost.

What to Consider While Calculating the Cost of an Artificial Sports Turf Field

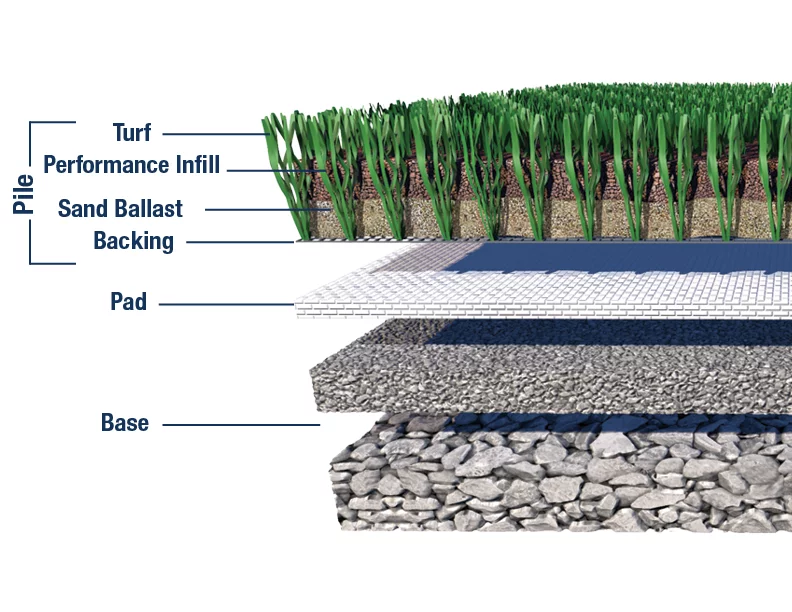

A synthetic turf field isn’t just made up of turf carpet and infill: it’s an intricate system with several different components and a meticulous installation process. Your costs start from preparing the ground for installation and end when you recycle or dispose of the turf. Here’s a list of everything you should consider while calculating the amount you’ll actually spend on the turf system.

The Purpose of Your Artificial Turf Field

Sports differ in their playing surface requirements. For instance, football and soccer fields demand highly durable turf that mimics natural grass. The systems may come with longer blades and specific infill types to support intense foot traffic, which impact costs. Baseball and softball fields require varied surface textures and densities for different zones, adding to installation complexities. Field hockey prefers shorter fibers to ensure fast, predictable play. Multi-use fields are a common approach, which need to balance the demand from various sports, necessitating versatile, advanced materials. These sport-specific requirements for material quality, safety, design, performance and maintenance directly impact the overall cost of your artificial sports turf.

Planning and Design

Before any field-building work begins, there needs to be detailed planning. This phase involves comprehensive site analysis, environmental assessments, and the development of detailed designs that accommodate the specific needs of the intended use. The complexity of the design, which may include drainage systems, underlayment, turf quality, and additional features like lighting, fencing, and seating, directly influences the project’s cost. Effective planning and design is a necessary step to ensure that the field meets performance and safety standards. A professional designer can also identify potential cost savings and efficiencies, ultimately affecting the project’s budget and long-term impact.

You may need to hire different professionals, like engineers, landscape architects, and design consultants at this stage. Factor their fees in.

Prep Work for an Artificial Turf Field

Whether you’re considering a new artificial turf field, or just getting an old one replaced, a lot of prep work goes into it before any recommendations are made. This includes safety and performance testing and site preparation.

If you’re planning to replace your field, the process will begin with removing the turf and infill without damaging the base and/or pad beneath. Your provider will likely conduct tests to ensure the base is suitable for another lifecycle of turf. drainage and planarity are still accurate. This is an advantageous approach to avoid costly surprises after the new surface is installed. Then there is site preparation, including earthwork, grading, and utilities.

If you’re looking to install a new field, your providers will likely conduct a survey of the field, geotechnical analysis, and gather the necessary permits for the work to take place. A new field is about twice as expensive as a replacement.

The Cost of an Artificial Turf System

Higher-quality synthetic turf systems result in higher initial costs. The product range of individual suppliers includes artificial turf with different features and in different price categories. Top-quality synthetic turf for a football field costs approximately $5 – $10 per square foot for a field replacement and $7-$14 per square foot for a field conversion. Where the project falls in this range depends on components, such as the shockpad, infill, logos, linework, fiber type and drainage system.

Try our Synthetic Turf System Recommender.

Condition of Gravel Base and Drainage System

It is usually cheaper to replace an existing field than to build one from scratch. In most cases, the underlying infrastructure can be reused, thus reducing the overall costs.

The Size of Your Artificial Turf Field

Both the turf and the underlying drainage layer are priced per square foot. As size goes up, the overall cost per square foot goes down, and as size goes down, the price per square foot goes up. This is because you lose efficiency and have sunk costs with a smaller job. If the field is larger, production and installation costs can be spread out further. For example, a softball infield is going to be more per/sf than a 2-field soccer complex. An obstacle-free perimeter must be factored into the cost calculation: after all, the comfortable, safe surface can’t end abruptly at the touchline.

Geographical Location

Labor and shipping costs can differ depending on the state in which the artificial turf is being installed, and how far away the manufacturing facility is from your site. Prices tend to be higher in urban areas than in rural areas. If you’re located in or near a floodplain, you will need to factor in more time and costs due to the regulatory requirements for these situations.

The Bells and Whistles

There are other aspects of the turf field that may or may not be optional. This includes tracks, dugouts, fencing, goalposts, seating, lighting, and features that ensure the field is accessible to users. Most importantly, if you’re going for a customized design, such as a club logo or a branded end zone, that will incur additional costs.

Compliance

To build a field, you’ll need to pay the relevant permits and legal fees required for construction approval. Meeting local regulations and standards for safety, environmental impact, and accessibility can add to the project’s cost.

Maintenance

Proactive, regular maintenance is crucial for extending the lifespan of your synthetic turf field, making it a worthwhile investment. This essential upkeep, requiring dedicated time, labor, utilities, and equipment, not only preserves the turf’s condition and appearance but also maximizes its usability and safety over the years. The better you maintain the turf, the longer you can use it.

Maintenance costs for artificial turf fields include:

- Routine cleaning and contact disinfectant

- Infill top-off or redistribution

- Controlling weeds

- Repairs for minor damages

- Performance testing

You can minimize a lot of these expenses by using your field provider’s service

packages – you’ll save on equipment, not to mention the price of expensive mistakes.

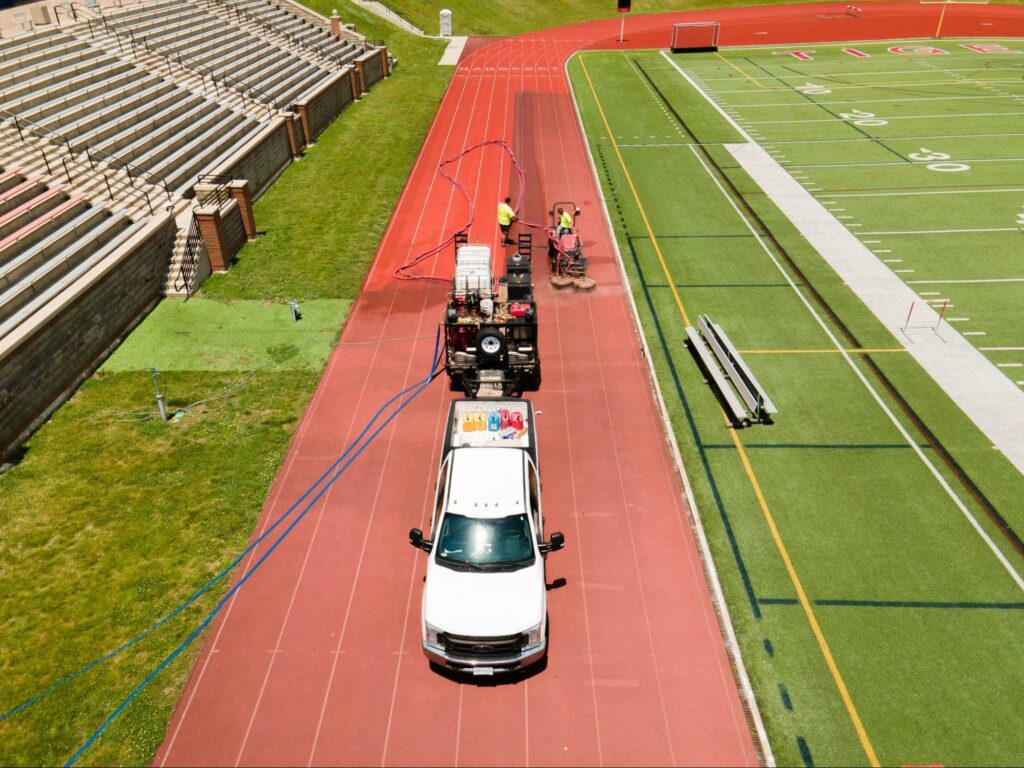

Motz’s annual deep clean & field testing services protect, improve, and help you get the most from your synthetic turf sports field.

End-of-Life Disposal

Selecting the appropriate infill for your synthetic turf sports field can slash disposal costs by up to 90%, turning into savings as substantial as $100,000 in some regions. Given that infill accounts for about 90% of the system’s weight, it significantly influences disposal expenses. Opting for an infill like Envirofill®, which can be reclaimed and reused in new turf installations, not only saves considerable amounts of money but also prevents over 500,000 pounds of material from being dumped in landfills (that’s 15 dumpsters). Over years of innovation and experimentation, Motz has mastered the process of reducing the waste by approximately 95% through its Zero Waste process.

Learn more about Motz’s Zero Waste fields here.

How Economical is Your Artificial Turf Field?

The best measure for assessing the cost of an artificial turf field project is the cost per year of use. This metric takes into account the total costs, including everything we discussed above, ongoing maintenance expenses, and the total utilization time over the field’s lifespan. The calculation would be:

[Total Cost+(Annual Maintenance Cost×Lifespan)]÷Lifespan

For example, if the total cost to install an artificial turf field is $1,000,000, requiring $5,000 per year in maintenance, with an expected lifespan of 10 years, the cost per year of use would be:

[$1,000,000 + ($5,000 x 10)]÷ 10 = $105,000 per year.

Don’t compare the prices of different providers and turfs based on the price tag alone. Consider how much you’ll be spending per year and make your decision.

The right products can help you get more years out of your field or be used for multiple turf lifecycles. This may include a higher cost upfront, but saves you money throughout the life of your field. Motz infill products like Envirofill® and Safeshell®, are premium products that focus on the long game costs, maintenance, longevity, and consistency of the surface of your synthetic turf sports field. While there is an upfront premium to choosing Envirofill®, the premiums are smaller when considered over two life cycles (about 16 years).

The benefits of a life cycle cost mindset will provide you with a winning strategy and the right products to create a high-performance sports field that will last the long game.

How Much Does A Football Field Cost?

For a standard-sized football field, which is approximately 80,000 square feet, a conservative budget would be $5-$10 per square foot for a field replacement and $7-$14 per square foot for a field conversion. However, considering all components of the installation, including materials, labor, and surface conditions, the total cost can reach up to around $2,000,000. These are just estimates. Contact a turf installation company like Motz for an accurate projection.

4 Tips To Plan And Budget For The Cost Of A Synthetic Turf Sports Field

1. For an Accurate Cost Estimate – Ask Motz

Cost estimates are complex: leave these calculations to sports field experts. Start by reaching out to a designer who is also a civil engineer or landscape architect, or find a design-build team. This brings in multiple perspectives, which ensures that various facets are considered.

2. Seek One Point of Responsibility for Your Turf and Base

Select one company to be responsible for both the turf and the base. Otherwise, you’ll need separate contracts for the base contractor and the turf contractor. Should issues arise with the base during the field’s warranty period, such as settling or drainage, the synthetic turf must be cut open, the issue addressed, and then the turf put back together. The question of who pays for what gets complicated. We recommend hiring a full-service synthetic turf contractor, like the Motz team, who can manage the entire project seamlessly.

3. Find Trusted Synthetic Turf Sports Field Builders

It’s essential to hire a well-qualified sports field builder from the American Sports Builders Association’s (ASBA) Certified Field Builder (CFB) list. A CFB is an individual who meets the high standards set forth by the ASBA with respect to sports field construction and maintenance.

To become a CFB, the builder has to pass a rigorous exam to demonstrate a high level of expertise and competency. By hiring a company that employs CFBs, you can rest easy, knowing that your facility is in good hands.

Motz is a proud member organization of ASBA, and we also have four CFBs on staff. Between these four individuals, they have overseen 500+ synthetic turf field projects.

4. Start Early in the Process

As detailed as it may be, a quote will never give you the full picture of how the whole field replacement or field installation process will work. Begin by selecting and consulting the right field builder early on, so they can coach you through the process to ensure you’re prepared for what field building entails.

Need More Info? Contact the Motz Team

Do you have questions about costs related to synthetic turf sports field replacement? Connect with a Motz specialist to get your questions answered.

Similar Blogs