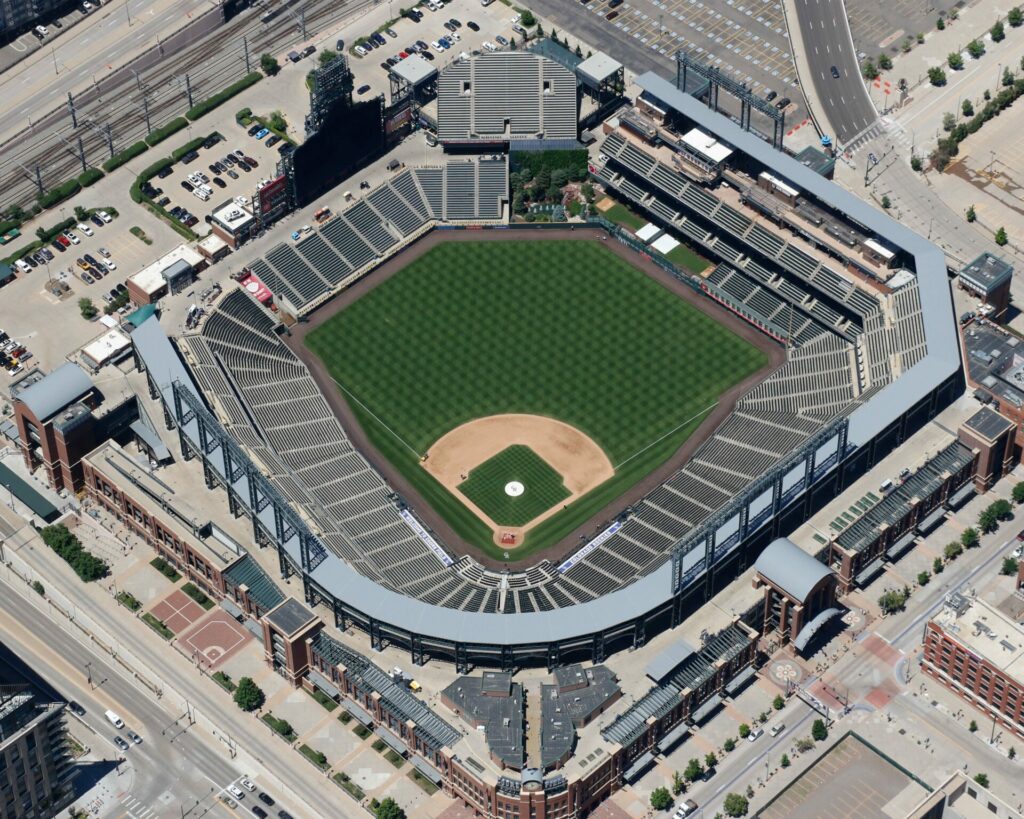

Churchill Downs

Project Overview

Churchill Downs is a horse racing complex with a capacity of roughly 170,000. Located in Louisville, Kentucky, the facility first opened in 1875 and is home to the iconic Kentucky Derby, the longest-running American sports event. In order to keep up-to-date with new industry regulations, Churchill Downs initiated its first significant upgrade to the historic grass track in over 30 years. Recognized for its expertise in building high-performance sports fields, Motz joined forces with Calhoun Construction, STRI, a European racetrack consultant, and Dr. Trey Rogers, Michigan State University agronomy professor, to take on these momentous improvements. Planning, designing, and building the new grass track at Churchill Downs all took place during the pandemic, adding myriad challenges that Motz overcame by working closely with the entire team to mitigate any issues and finding collaborative solutions that kept the project as close to the plan and budget as possible. After upgrading the root zone, irrigation, and drainage system on the new 85’ wide track, Churchill Downs reopened and jockeys were able to use the reconstructed track for the first time in the spring of 2022.

The Situation

In operation for nearly 150 years, the horse racing tracks at Churchill Downs require more than regular maintenance to meet industry requirements. Since the facilities were last updated, new rules and regulations impacting thoroughbred racing had been enacted, prompting Churchill Downs to find an expert that could help bring their track into alignment and elevate their natural grace racecourse to a new level of state-of-the-art professionalism. Management wanted to ensure industry compliance by re-establishing uniform grass levels, upgrading drainage and irrigation components, and increasing the track width. Although the construction process would be similar to any high-performance natural grass sports field, the scale certainly wasn’t. Nearly 25,000 cubic yards of track needed to be excavated and replaced, six miles of new drainage lines installed, and more than 10 acres of Tahoma 31 sod laid down. Selected for their proven professionalism and 40+ years of industry expertise, Motz took on this historic upgrade as their first horse racetrack renovation.

The Play

Because Churchill Downs’ team did not allow any heavy machinery on the dirt track, every piece of equipment and material passed through the tunnel under the dirt track to the interior grass track. To manage costs, field specialists stockpiled as much of the clean rootzone sand as possible and blended it on-site with new sand to produce the final specified product. The existing track materials that were unusable for the new track were repurposed offsite by the facility’s landscaping partner. The site was excavated, the subgrade established, and new drainage and irrigation installed; then, 6” of gravel drainage raft and 12” of rootzone sand were placed and laser graded. After applying pre-plant fertilizers, the finished rootzone was turned over to the owner. The Bermudagrass sod was supplied and installed under an owner-directed contract with a local grower. Motz also managed the railing and timing system upgrades, including cameras, sensors, and other specialized race-monitoring technologies. The upgraded grass track was ready for use by the spring of 2022.

Grass track reconstruction was one of Churchill Downs’ largest projects. Being able to rely on Motz’s extensive expertise made life a lot less stressful. Their continuous communication kept everyone up to speed and their willingness to flex and adapt kept the project on time and on budget.

The Win

- CUSTOM DESIGN:

Renovations to the world-famous horse race track were expertly handled by the team of professional designers and builders Churchill Downs assembled, with Motz, Calhoun Construction, STRI, and Dr. Trey Rogers collaborating effectively throughout the process. The landmark status of this historic racetrack posed unique challenges that required Motz’s elite problem-solving skills and flexibility, in addition to their well-established expertise and experience.

- HIGH-TOUCH PROJECT MANAGEMENT:

Because of the pandemic, much of the planning and communication between Motz and the design consultants were handled virtually. This demanded laser-focused and high-touch management throughout the process. The Motz Group remained in constant contact with the team and Churchill Downs’ leadership to resolve issues that arose during this singularly challenging time, working together to find budget-conscious solutions that met the industry standards required.

- ENHANCED PERFORMANCE:

The Motz team constructed a new 85’ wide natural grass track that accommodates four racing lanes. Upgrades to the root zone, irrigation, and drainage systems produced a state-of-the-art natural grass racetrack befitting the iconic Churchill Downs.

Ready to Get Started?

Interested in starting a project? Have questions about our process and products? Wherever you are in planning your dream field, we’re ready to walk through your specific needs, answer any questions you have, and talk through how our team of experts will be there to guide you every step of the way.