Sports Field Blog

Subscribe To Email Updates

Subscribe to our weekly newsletter and we’ll send updates straight to your inbox

Best Synthetic Turf for Baseball

What system is best for baseball systems?

Download our Baseball one pager here.

Natural baseball fields require a lot of maintenance to create an optimum playing surface. That maintenance is amplified by the Spring start of baseball season, typically the wettest time of year. A noticeable trend is schools converting their baseball fields into synthetic turf to remove this maintenance burden and drastically reduce rain outs. Many of these schools are focusing primarily on the conversion of the infield, where the most amount of maintenance is required, while leaving the outfield natural turf. Other schools are choosing to install synthetic turf across the entire infield and outfield, overlapping the outfield with a soccer or football field to maximize its use. For these multi-use fields, we recommend designing the synthetic turf system to follow the traditional approach of a multi-use soccer/football field where shock attenuation is a top consideration.

Fields where only baseball will be played can be customized for optimum play. Below are insights into what to consider when designing and selecting a synthetic turf surface for baseball.

Top priorities for a baseball-specific synthetic turf field:

Speed

If a field is too slow then the player may need to travel further to field the ball, thereby allowing the runner to advance further. A slow field can significantly change the game and is something to avoid.

True roll

Consistently level surfaces that allow the ball to travel across the surface in a predictable way to the defensive player are preferred over fields with infill that mounds or becomes lumpy over time.

Flyout

Flyout is the movement of the infill above the turf blade when a ball strikes the surface. Systems with minimal flyout are preferred so the infill does not interfere with fielding the ball. Selecting an infill with a high bulk density such as Envirofill can reduce the volume of flyout by as much as 85%.

Natural turf baseball surfaces are unique compared to all other North American field sports because the sport is played across various types of surfaces: grass, infield clay and warning track material. Replicating those surfaces on a synthetic turf surface also requires a unique approach. Infield clay areas tend to be very firm. According to Penn State report (Brosnan 2015), the mean Gmax score of the infield clay areas across 15 different baseball fields was 170.97 with five fields recording Gmax scores above 200. This is compared to the Gmax score of well-maintained natural grass fields which is in the range of 70-115 G’s. The Gmax score indicates the likelihood of a head injury when an athlete’s head meets the surface; an event that is far less likely to occur in baseball then in other field sports.

Because shock absorption is less of a concern on a baseball field, a firm infill without a pad is an acceptable approach. Many warranties include a maximum Gmax score during the life of the field, so the turf manufacturer or contractor may require the owner to waive the Gmax portion of the warranty, acknowledging the unique approach to designing a baseball-specific synthetic turf system.

Beyond performance, there are a few considerations to get the longest life out of the synthetic turf field, especially in the very defined high wear areas such as the batter’s box and base slide paths:

- Select an infill that won’t prematurely wear down the fibers is key. We recommend staying away from angular infills or infills that compact such as angular sands.

- Using a slit film turf with thatch in the clay areas will reduce the flyout and improve wear resistance of the turf.

- Using a dual fiber (monofilament and slit film) in the grass areas of the infield will provide a more realistic look. If you want an even more realistic look, alter the heights of the turf blade, selecting a longer pile height turf for the grass areas and a shorter turf for the clay areas.

Warning Tracks

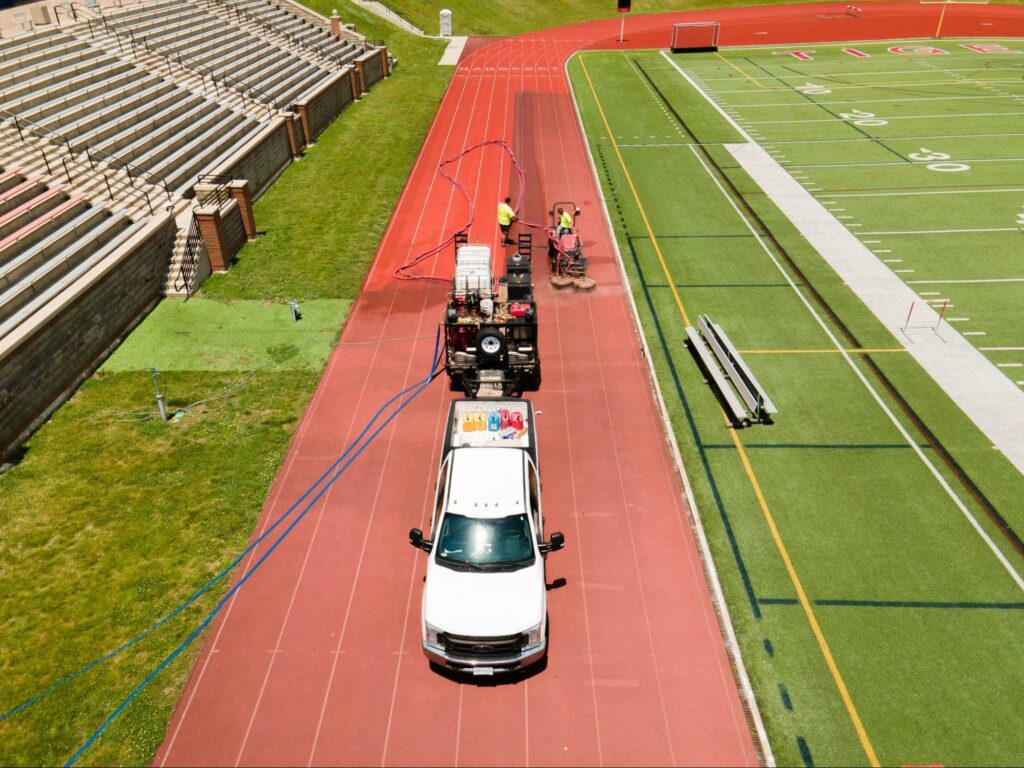

The main purpose of a warning track is to serve as a warning to players who are looking up in the air to field a ball. By being a different material, the player will not only feel the difference but will also hear the difference in material and realize they are close to the perimeter fence or wall. A perfect application for this area is 100% Safeshell. It not only feels different but has a noticeable sound difference when walked on.

Check out a few of our favorite baseball project highlights.

Sources:

Similar Blogs